When we first formulated our drink we thought it was perfect. As we grow and tell our story we welcome more people into our extended team: brokers, distributors, formulators, ingredient manufacturers, co-packers (facility that helps us blend and fill our cans), warehouses, logistics. We learn so much from everyone we talk to at demos, trade shows, events — hundreds, maybe thousands of people — and through all of this we’ve discovered better ways to do things, better ingredients, refined our taste buds, and obsessed over every detail.

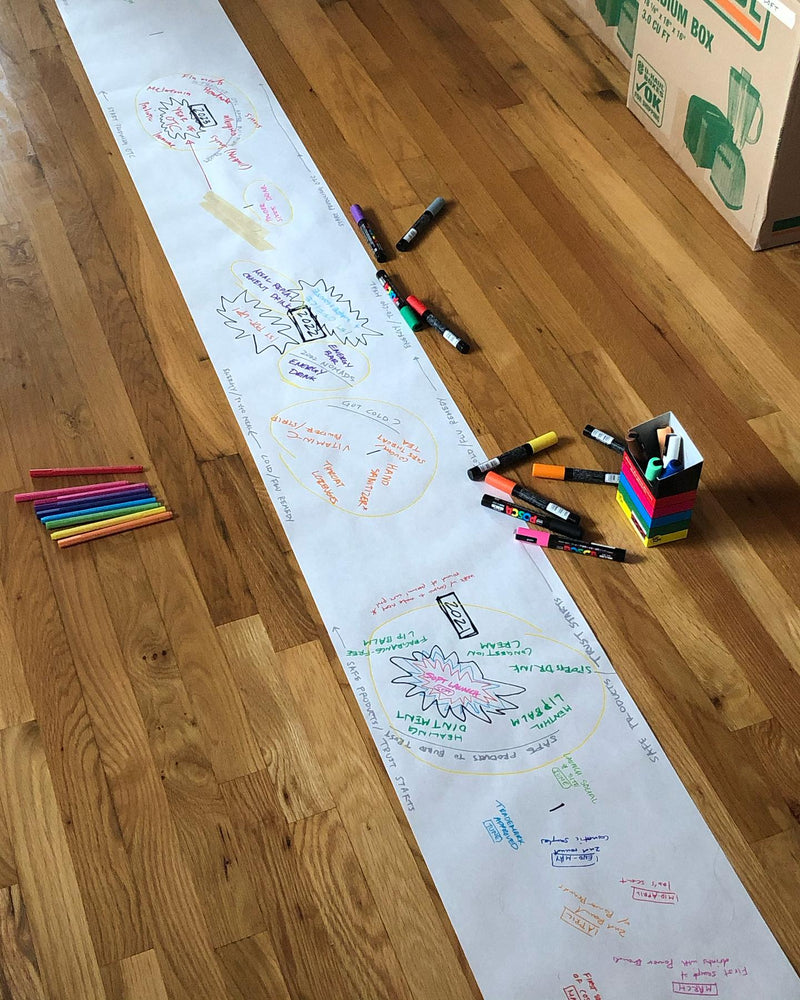

We source every ingredient ourselves — buying barrels of powders and liquids, empty cans and even the ends, printed sleeves, trays, and booking semi-trailers to lug our materials back and forth from LA to Vegas. We need legal paperwork and contracts, insurance, documentation, certificates of analysis of every ingredient. The number of moving parts involved in creating this single end product is... a lot. It’s also extremely capital intensive. We’re a two-person team, but the total number of people who touch this process could be in the hundreds. We were naive getting into this, but maybe that worked in our favor.

We ran this batch with a new co-packer in Vegas — one with a much better and bigger facility — but because our run was so small they had to squeeze it between larger jobs and couldn’t tell us exactly when it would be. They called us at 9am to tell us they’re running it at 3pm, so we packed ourselves in the car and drove 6 hours to Vegas. The run ended up being at 2am because their CO2 tank blew up.

As many would understand, we want to make things “perfect” before we put it out. Every little thing needs to be 100% just right. It’s tough to let go of this, but we’ve learned along the way that it’s actually better to put something out into the world and redesign and adjust as we go. MVP (Minimal Viable Product) allows for a greater capacity of feedback and consumer input. It’s just a V1. There’s going to be V2, V3, V4…

By no means is this journey complete, but we are happy to share our most recent iteration of the OEM Rehydrating Drink. After demo’ing our drink in grocery stores and events, we got valuable feedback about sugar preferences — we reduced our sugar to 5g, refined our electrolyte and mineral blend, and still kept our great taste. We also made the decision to remove CBD — an incredible ingredient, but also an expensive one that forced us to charge customers more. By removing it we’ve been able to lower our prices by 30% to $3.49 a can, making them more accessible. Without the CBD, we can also sell our drink to more retailers, making it easier to buy off-the-shelf.

Recently we’ve been fortunate enough to be part of amazing local shops like Psychic Wines, Ancient Ritual, Canal Market, Sip Snack, Regent Coffee, and more. The support we’ve had from a small group of people has kept us wanting to continuously improve our drink — it never gets old when someone tells us it’s the perfect drink.